Toll Manufacturing

Spray drying and blending bulk ingredients

Our human-grade facility specializes in spray drying food and nutraceutical ingredients as well as the blending of bulk ingredients. Utilize our state of the art equipment to manufacture your raw ingredients or blended finished foods with stringent quality testing and service that will meet and exceed your expectations.

Spray drying & blending high-quality bulk ingredients

Our perfected process results in the efficient production of free-flowing spray dried powders derived from a liquid feedstock. For assistance in large bulk ingredients we also provide blending services to ensure your ingredients are ready for use.

Tower Spray Dryers:

- Fluid Beds attached for optimal particle size control and optional lecithin addition.

- Optional Agglomeration

- Extensive experience with dairy products, foods and nutritional products

- Production drying capacities at multiple scales to meet customer needs

V Blenders:

- 200kg Blender Minimum Requirement: 200 kg

- 400 kg Blender Minimum Requirement: 400 kg

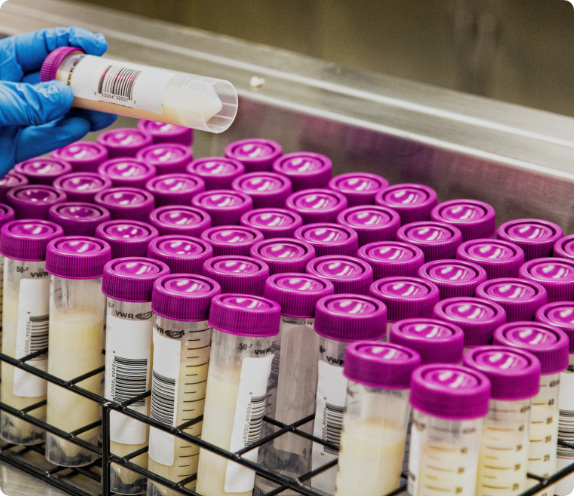

Quality and Safety

- Testing: Each lot is sampled and sent to Quality for testing

- Metal Detection and Rejection

- Heat Tunnel & Induction Sealing

- Product specifications and testing may be tailored to customer needs

- Finished Good Storage: Product is stored in Quarantine until testing is complete and product is released.

In-house quality laboratory

We have a skilled team and equipment that is coveted in the industry. We sample and test all incoming and outgoing items including raw materials and packaging components to ensure all specifications are met. Every step of our manufacturing process, material handling, product release, line clearance, employee training and standard operating procedures are timely, documented and maintained.